What Is a Heavy Duty Connector Insert and Why Is It Crucial in Industrial Applications?

2025-06-24

Heavy Duty Connector Inserts are core components in industrial connector systems, designed to ensure reliable electrical or signal connections in harsh environments. Whether used in machinery, automation systems, railway equipment, or renewable energy installations, these inserts provide the secure, stable, and high-performance connections required for demanding applications. But what exactly are they, and why are they so essential?

What Is a Heavy Duty Connector Insert?

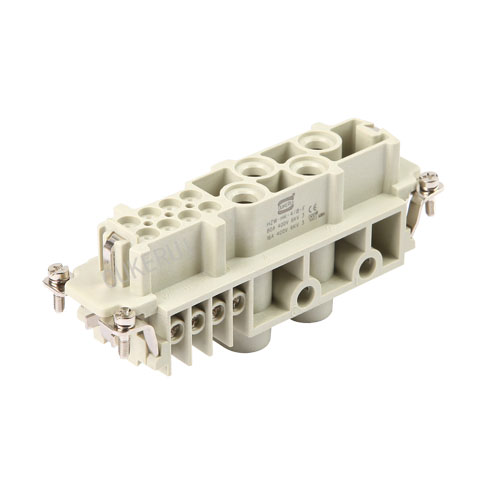

A Heavy Duty Connector Insert is the part of a multi-pin connector system that houses the electrical contacts or terminals. It fits inside a robust outer housing (typically made from die-cast aluminum or similar materials) and provides the connection interface for power, signal, or data transmission. These inserts are typically made from high-quality insulating materials like thermoplastics and are designed to withstand mechanical stress, vibration, and high temperatures.

They are available in various configurations, such as different contact numbers, current/voltage ratings, and termination styles (e.g., screw, crimp, spring, or push-in).

What Are the Key Features?

Heavy duty connector inserts are engineered for high performance and long-term reliability. Common features include:

High Pin Density: Multiple contacts in compact space to reduce wiring complexity.

Wide Voltage and Current Ratings: From signal-level (few mA) to high-power (hundreds of amps) applications.

Modular Design: Easily customized with different contact types—power, signal, data, or pneumatic.

Secure Locking: Precise fit inside housings ensures secure electrical connection.

Temperature and Chemical Resistance: Suitable for harsh industrial conditions.

What Are the Benefits?

There are several advantages to using heavy duty connector inserts:

Reliability in Harsh Environments: Designed to perform under mechanical stress, vibration, dust, and moisture.

Quick Installation and Maintenance: Modular and standardized design allows fast connection and disconnection.

Customizable Solutions: Flexible combinations of contacts for power, control, and communication.

Safety: Secure locking mechanisms reduce the risk of disconnection or failure.

Longevity: High-quality materials and construction ensure a long service life.

Where Are They Used?

Heavy duty connector inserts are used across a wide range of industrial sectors, including:

Factory Automation and Robotics

Railway and Transportation Systems

Renewable Energy (Wind, Solar)

Construction Equipment

Heavy Machinery and Mining Equipment

Control Panels and Switchgear

Their versatility makes them suitable for both fixed and mobile equipment installations.

How to Choose the Right Insert?

When selecting a heavy duty connector insert, consider the following:

Number of Contacts: Based on the application’s wiring requirements.

Current and Voltage Ratings: Must match or exceed the electrical demands of your equipment.

Type of Termination: Screw, crimp, or spring connection depending on assembly preference.

Compatibility with Housing: Make sure the insert matches the connector shell or frame you are using.

Environmental Requirements: Check resistance to water, dust, chemicals, and temperature.

Conclusion

Heavy Duty Connector Inserts are the heart of industrial connector systems. They ensure safe, reliable, and efficient transmission of electrical power and signals in even the most challenging environments. With their modularity, durability, and customization options, they are indispensable components for modern industrial automation and heavy equipment connectivity.