Types of Gas Igniters

2024-07-19

A gas igniter is a device used to ignite gas in appliances such as stoves, ovens, furnaces, and grills. It creates a spark or a small flame to light the gas, providing a reliable and safe method for initiating combustion. Here’s a detailed look at gas igniters:

Types of Gas Igniters:

1. Piezoelectric Igniters:

- Mechanism: Generates a spark using the piezoelectric effect, which involves applying pressure to a crystal to produce an electric discharge.

- Usage: Commonly found in gas grills, portable stoves, and some older gas appliances.

- Pros: Simple design, no need for external power source.

- Cons: Requires manual pressing to generate the spark.

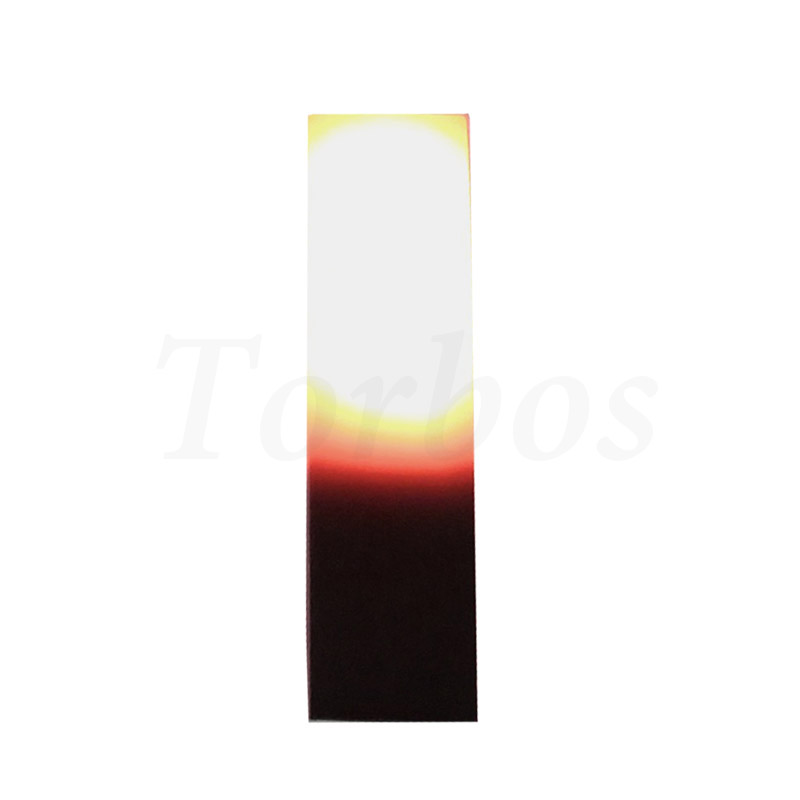

2. Hot Surface Igniters (HSI):

- Mechanism: Uses an electrically heated element (usually silicon carbide or silicon nitride) to a high temperature, which ignites the gas.

- Usage: Often used in modern furnaces, boilers, and gas ovens.

- Pros: Reliable and efficient ignition, often integrated with safety systems.

- Cons: Requires a power source, the element can be fragile and may need replacement over time.

3. Spark Igniters (Electronic Igniters):

- Mechanism: Uses an electronic circuit to generate a high-voltage spark.

- Usage: Found in gas stoves, ovens, and some water heaters.

- Pros: Reliable, can be activated automatically, suitable for continuous ignition systems.

- Cons: Requires a power source, can be more complex than piezoelectric systems.

Key Components:

1. Ignition Module: The component that generates the spark or heats the element.

2. Electrode: The part that the spark jumps across or that heats up.

3. Wiring: Conducts electricity to the ignition module and electrode.

4. Safety Systems: Modern igniters often include sensors and controls to ensure safe operation, such as flame sensors and thermocouples.

Common Problems and Solutions:

1. No Spark or Flame:

- Possible Causes: Faulty ignition module, broken electrode, loose or damaged wiring.

- Solutions: Check and replace the ignition module, electrode, or wiring as needed.

2. Intermittent Ignition:

- Possible Causes: Dirty or corroded electrode, improper gap between electrodes, fluctuating power supply.

- Solutions: Clean the electrode, adjust the gap, check the power supply.

3. Delayed Ignition:

- Possible Causes: Slow heating of hot surface igniter, low gas pressure.

- Solutions: Check the igniter for proper operation, ensure adequate gas pressure.

4. Igniter Continuously Clicking:

- Possible Causes: Faulty ignition switch, moisture around the igniter, electrical issues.

- Solutions: Replace the ignition switch, dry the area around the igniter, inspect for electrical problems.

Maintenance Tips:

1. Regular Cleaning: Keep the igniter and surrounding area clean to prevent buildup of grease, dirt, or debris.

2. Inspect Connections: Periodically check the wiring and connections for signs of wear or damage.

3. Test Functionality: Regularly test the igniter to ensure it is functioning properly.

4. Replace When Needed: Replace worn or damaged igniters promptly to maintain safety and efficiency.

Safety Considerations:

1. Proper Installation: Ensure the igniter is installed correctly according to the manufacturer’s instructions.

2. Avoid DIY Repairs: Unless you are experienced with gas appliances, it is best to have repairs performed by a qualified technician.

3. Use Genuine Parts: Always use genuine replacement parts to ensure compatibility and safety.

4. Turn Off Gas Supply: Before performing any maintenance or repairs, turn off the gas supply to the appliance.

Gas igniters are crucial components in ensuring the reliable and safe operation of gas appliances. Regular maintenance and prompt replacement of faulty parts can help prevent issues and maintain efficient performance.