Key Aspects Related to Auto Panel Injection Parts

2024-06-24

Auto panel injection parts refer to plastic or metal components used in the automotive industry, specifically manufactured through injection molding processes. Here are the key aspects related to auto panel injection parts:

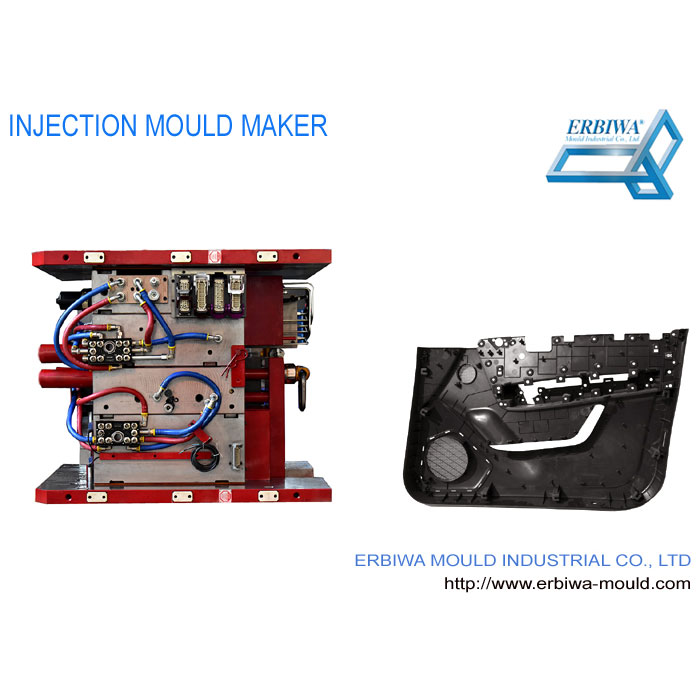

1. Injection Molding Process: Auto panel injection parts are produced using injection molding, a manufacturing process where molten material (usually plastic or metal) is injected into a mold cavity under high pressure. The material then solidifies to form the desired shape of the auto panel part.

2. Materials:

- Plastic: Common plastic materials used for auto panels include ABS (Acrylonitrile Butadiene Styrene), PP (Polypropylene), PC (Polycarbonate), and various blends and composites tailored for specific automotive applications (e.g., impact resistance, thermal stability).

- Metal: Some auto panels, especially structural or exterior components, may be made from metals like aluminum or steel, using processes such as die casting or metal injection molding (MIM).

3. Types of Auto Panels: Auto panel injection parts encompass a wide range of components used in vehicles, including:

- Interior Panels: Dashboard panels, door panels, center console parts, and trim components.

- Exterior Panels: Bumpers, fenders, side panels, grille components, and other body panels.

- Functional Components: Air vents, cup holders, storage compartments, and other functional parts integrated into automotive interiors.

4. Design Considerations: Auto panel parts must meet stringent requirements for dimensional accuracy, durability, aesthetics, and functional integration within the vehicle. Design considerations often include provisions for assembly, attachment points (such as clips or fasteners), and integration with other vehicle systems (e.g., electrical components, HVAC systems).

5. Surface Finishes: Depending on the application, auto panel injection parts may require specific surface finishes such as textures, paints, coatings, or decorative finishes to meet aesthetic and functional requirements (e.g., scratch resistance, UV protection).

6. Quality and Testing: Automotive industry standards require rigorous quality control and testing for auto panel parts to ensure they meet performance, safety, and regulatory standards (e.g., crashworthiness, emissions standards).

7. Production and Supply Chain: Auto panel injection parts are typically produced by automotive suppliers or manufacturers specializing in injection molding. They are integral parts of the automotive supply chain, serving OEMs (Original Equipment Manufacturers) and tier suppliers.

8. Advancements and Innovations: The automotive industry continually explores advancements in materials, manufacturing processes (such as lightweighting), and design techniques to improve performance, efficiency, and sustainability of auto panel parts.

Overall, auto panel injection parts play a crucial role in vehicle design and manufacturing, contributing to both the aesthetic appeal and functional performance of modern automobiles.