Considerations regarding injection mold bases

2024-01-08

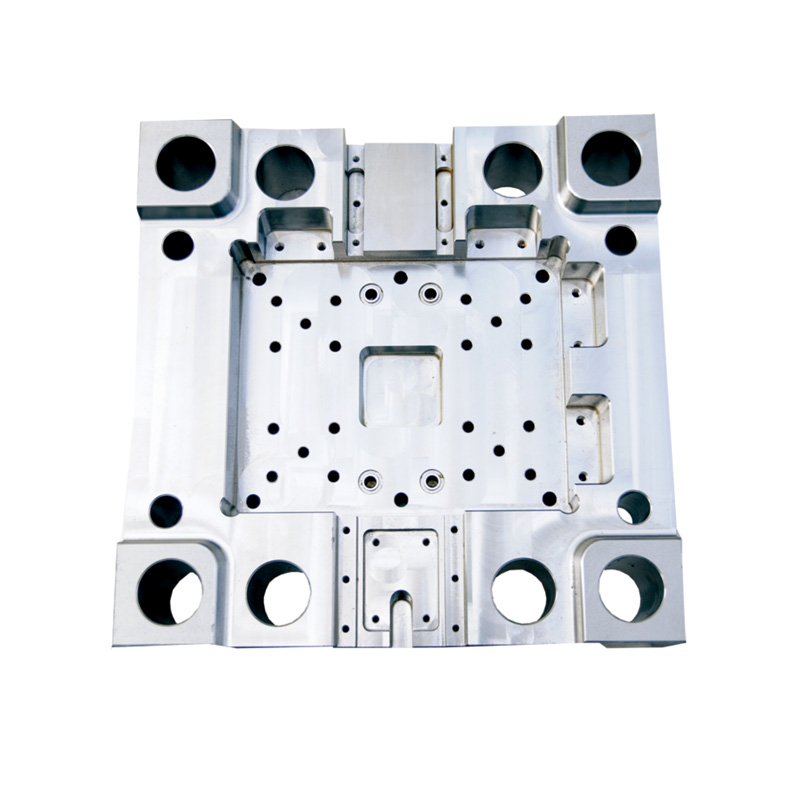

An injection mold base is a critical component in the construction of injection molds used in the plastic injection molding process. It serves as the foundation or support structure for the various components of the mold, including the core, cavity, and other mold inserts. The injection mold base provides the necessary rigidity, support, and alignment for the mold components to function together seamlessly. Here are key features and considerations regarding injection mold bases:

1. Material:

- Injection mold bases are typically made from high-quality materials, such as tool steel or alloy steel. The choice of material depends on factors such as the expected production volume, the type of resin being molded, and the required durability of the mold.

2. Precision Machining:

- Injection mold bases undergo precise machining processes to achieve tight tolerances and ensure accuracy. CNC (Computer Numerical Control) machining is commonly employed to achieve the necessary precision in the creation of mold base components.

3. Standardization:

- Many injection mold bases adhere to industry standards, such as those set by organizations like DME (Mold Base and Mold Component Supplier) or HASCO (International Standard for Mold Components). Standardization facilitates interchangeability and compatibility between different mold components.

4. Cavity and Core Inserts:

- The injection mold base accommodates cavity and core inserts, which define the shape and features of the final plastic part. These inserts are securely mounted within the mold base to ensure proper alignment and registration.

5. Cooling Channels:

- Injection mold bases often incorporate channels for cooling water to help regulate the temperature during the molding process. Proper cooling is crucial for achieving consistent part quality and minimizing cycle times.

6. Ejector System:

- The mold base integrates an ejector system designed to efficiently remove the molded parts from the mold. The ejector system typically includes pins or sleeves that move in coordination with the molding machine's ejector mechanism.

7. Runner and Gate System:

- The mold base may include components related to the runner and gate system, directing the flow of molten plastic into the mold cavity. This system influences the molding process parameters and is designed for efficient material flow.

8. Alignment and Registration:

- Injection mold bases are engineered to ensure proper alignment and registration of the core and cavity inserts. Accurate alignment is crucial for producing high-quality, dimensionally stable parts.

9. Durability and Wear Resistance:

- Mold bases are subjected to repeated cycles of injection molding, necessitating durability and resistance to wear. High-quality materials and surface treatments contribute to the longevity of the mold base.

10. Customization:

- While standard mold bases are available, customization may be required for specific applications. Custom features may include special cooling arrangements, additional cavities, or unique configurations based on the requirements of the molded parts.

11. Surface Finish:

- The surface finish of the injection mold base is important for the appearance and quality of the molded parts. A smooth surface finish helps prevent defects in the final product.

Injection mold bases play a crucial role in the injection molding process, providing the structural integrity and precision required for the production of plastic parts. Proper maintenance and care of the mold base contribute to its longevity and overall performance in the manufacturing process.