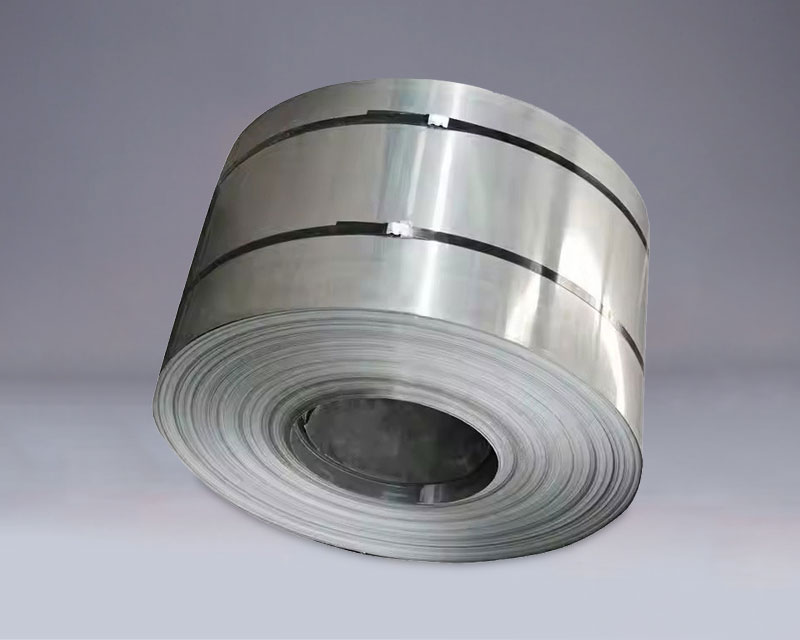

Cold-Rolled Steel Coil: The Backbone of Modern Manufacturing

2025-04-03

In the world of manufacturing and construction, steel plays a critical role in building the structures that power our economy. One of the most essential forms of steel used in various industries is cold-rolled steel coil. This material is known for its precision, durability, and versatility, making it a top choice for a wide range of applications.

In this blog, we’ll dive deep into what cold-rolled steel coils are, how they’re made, their uses, and the many advantages they offer across different industries.

What is Cold-Rolled Steel Coil?

Cold-rolled steel is steel that has been processed at room temperature, below its recrystallization temperature. The process involves passing hot-rolled steel through rollers at ambient temperatures to reduce its thickness. As a result, cold-rolled steel coil is smoother, more uniform in thickness, and often stronger than its hot-rolled counterpart.

Cold-rolled steel coils are commonly sold in rolls and can undergo various treatments to suit specific applications. The final product is usually coated or further processed to enhance its properties.

How is Cold-Rolled Steel Coil Made?

The production of cold-rolled steel coils starts with hot-rolled steel. The hot-rolled steel is heated to a high temperature and then processed through a rolling mill. Once the steel has been cooled down, it is subjected to cold rolling, which reduces the thickness and improves the overall surface finish.

Here’s a breakdown of the key steps in the cold-rolling process:

1. Pickling: The hot-rolled steel is cleaned to remove any rust, scale, or impurities. This is typically done through an acid bath.

2. Cold Rolling: The steel is passed through a series of rollers at room temperature, reducing its thickness and increasing its length. This process enhances the material’s surface finish and mechanical properties.

3. Annealing: The cold-rolled steel may be heated and cooled in a controlled environment to relieve internal stresses and make the steel more workable.

4. Coating and Finishing: The cold-rolled steel is then coated with a layer of material like zinc or a protective film to enhance its corrosion resistance. In some cases, the surface can be polished to a high gloss for specific applications.

5. Coiling: Finally, the processed steel is wound into coils, ready for transport to customers or further processing.

Benefits of Cold-Rolled Steel Coil

1. Improved Surface Finish

Cold-rolled steel coils have a smooth, high-quality surface that is often more aesthetically pleasing than hot-rolled steel. This makes it ideal for applications where the appearance of the steel is crucial, such as in appliances, automotive parts, and consumer electronics. The smooth finish also allows for better paint adhesion, which is why cold-rolled steel is often used in applications that require painting or coating.

2. Higher Strength and Durability

Due to the cold-rolling process, cold-rolled steel typically has superior mechanical properties compared to hot-rolled steel. The process aligns the steel’s grain structure, resulting in a stronger, more durable material. This makes it an excellent choice for applications where strength and toughness are essential, such as in the construction of heavy machinery and structural components.

3. Tight Tolerances

Cold-rolled steel is processed under highly controlled conditions, which results in more precise thickness tolerances and better dimensional accuracy. This is particularly important in industries where precision is critical, such as the automotive and aerospace sectors.

4. Versatility

Cold-rolled steel coils are incredibly versatile and can be used in a wide range of applications. Their ability to be further processed into other materials—such as galvanized steel, stainless steel, or alloyed steel—makes them an indispensable material in various industries. Cold-rolled steel can be used in everything from thin sheets for appliances to thick plates for structural components.

5. Enhanced Formability

Despite its increased strength, cold-rolled steel retains its ability to be easily formed into various shapes and sizes. This makes it an ideal material for manufacturers who need to shape steel into custom products, such as auto parts, structural beams, or containers.

Applications of Cold-Rolled Steel Coil

Cold-rolled steel coils are used across many industries, thanks to their strength, versatility, and aesthetic appeal. Some of the most common applications include:

1. Automotive Industry

Cold-rolled steel is widely used in the automotive industry for parts such as body panels, frames, and other structural components. Its strength and durability make it ideal for withstanding the stresses and impacts that vehicles are subjected to during operation. Additionally, the smooth surface finish of cold-rolled steel makes it perfect for painting, which is essential for the automotive industry.

2. Construction and Infrastructure

In construction, cold-rolled steel is used in a variety of structural applications, including beams, columns, and frames. The high strength of cold-rolled steel allows it to support heavy loads, making it suitable for large-scale projects like bridges, buildings, and infrastructure.

3. Consumer Appliances

Many household appliances, such as refrigerators, washing machines, and ovens, use cold-rolled steel for their outer casing. The smooth surface finish and corrosion resistance of cold-rolled steel help protect these appliances and improve their appearance.

4. Electrical and Electronics Industry

Cold-rolled steel is used in the production of electrical components and electronic devices. Its strength, durability, and precision make it ideal for applications that require high-performance materials, such as in the manufacturing of transformers, electrical enclosures, and motor parts.

5. Metal Furniture and Fixtures

Cold-rolled steel is also a popular choice for manufacturing metal furniture and fixtures. Its strength and aesthetic appeal make it ideal for creating furniture that needs to support weight while maintaining an attractive appearance.

6. Shipbuilding and Heavy Machinery

In industries like shipbuilding and heavy machinery manufacturing, cold-rolled steel is used for producing parts that require both high strength and corrosion resistance. Its ability to withstand harsh environmental conditions makes it the material of choice for constructing durable equipment and structures.

Conclusion

Cold-rolled steel coil is one of the most important materials in modern manufacturing and construction. Thanks to its improved surface finish, higher strength, precise tolerances, and versatility, it plays a pivotal role in a wide range of industries. Whether it's for automotive parts, construction beams, or household appliances, cold-rolled steel remains a go-to material for high-performance applications.

As the demand for durable and sustainable materials grows, cold-rolled steel coils will continue to be at the heart of innovation and manufacturing, shaping the world around us. With its unmatched combination of strength, formability, and aesthetic appeal, cold-rolled steel is indeed the backbone of modern industry.