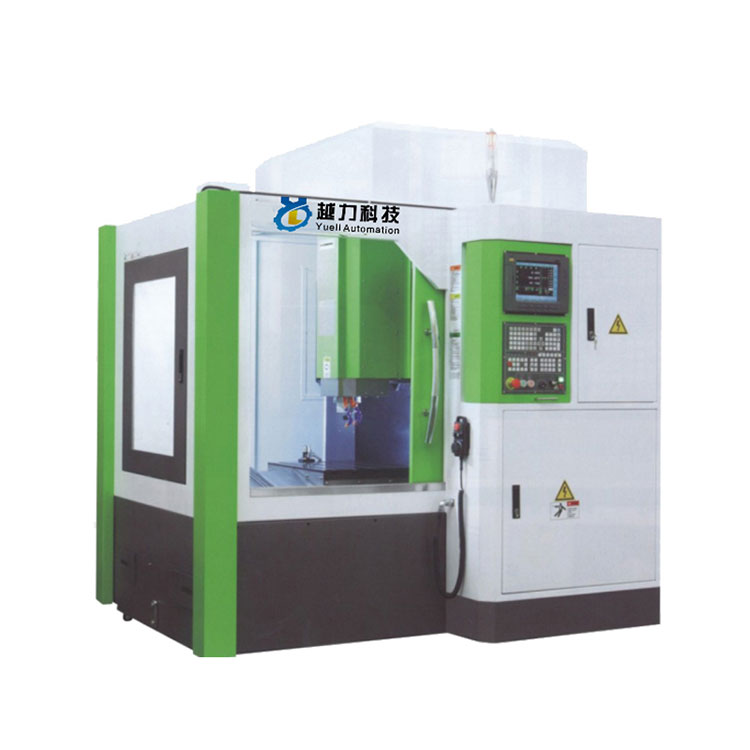

CNC Machining Center: Precision and Power in Modern Manufacturing

2025-04-25

In the world of advanced manufacturing, few tools have transformed production as significantly as the CNC machining center. Known for its high precision, flexibility, and efficiency, a CNC machining center is the backbone of many industries including aerospace, automotive, electronics, and custom part fabrication.

What Is a CNC Machining Center?

A CNC machining center is a computer-controlled machine that performs a variety of machining tasks such as drilling, milling, boring, and tapping. CNC stands for Computer Numerical Control, which means that the machine is operated through programmed instructions rather than manual control. This allows for extreme accuracy and repeatability across complex designs and high-volume production runs.

There are several types of CNC machining centers, including vertical, horizontal, and multi-axis machines. Each type is suited to specific applications depending on the geometry and scale of the components being produced.

Why CNC Machining Centers Matter

CNC machining centers have become essential in modern production for several key reasons:

- Precision: These machines can achieve extremely tight tolerances, often within microns, making them ideal for components that require exact specifications.

- Efficiency: Automated operations allow for faster production with minimal human intervention, reducing labor costs and cycle times.

- Versatility: CNC machining centers can work with a wide range of materials including metals, plastics, and composites.

- Consistency: Once a program is written and tested, the same part can be produced repeatedly with identical quality.

- Complexity: Advanced multi-axis machines can produce intricate shapes and geometries that would be nearly impossible to create manually.

Applications Across Industries

CNC machining centers are used in countless industries, providing solutions for everything from prototypes to full-scale production. Some common applications include:

- Engine components and transmission parts in the automotive industry

- Aircraft structural parts and turbine components in aerospace

- Precision molds and dies for injection molding

- Medical devices and surgical instruments

- Consumer electronics housing and components

Because of their flexibility and accuracy, CNC machining centers are also popular in custom manufacturing and small-batch production.

What to Look for in a CNC Machining Center

When choosing a CNC machining center, several factors should be considered:

- Machine Size and Travel Range: Match the size of the machine with the dimensions of the parts you plan to produce.

- Spindle Speed and Power: Higher spindle speeds and power ratings allow for faster cutting and better finishes.

- Axis Configuration: More axes mean more complex capabilities. A 5-axis machine, for example, can approach the workpiece from multiple angles in a single setup.

- Software Compatibility: The machine should work with your preferred CAD or CAM software to streamline the design-to-production workflow.

- Durability and Support: A robust frame, high-quality components, and good technical support ensure long-term performance and fewer downtimes.

Conclusion

The CNC machining center represents the heart of precision manufacturing. Whether you're producing simple brackets or intricate aerospace components, these machines offer the power, precision, and reliability needed in today’s competitive market. As technology continues to advance, CNC machining centers will remain at the forefront of innovation, driving progress across virtually every industry.