Ball Valve: A Reliable Solution for Flow Control

2025-07-17

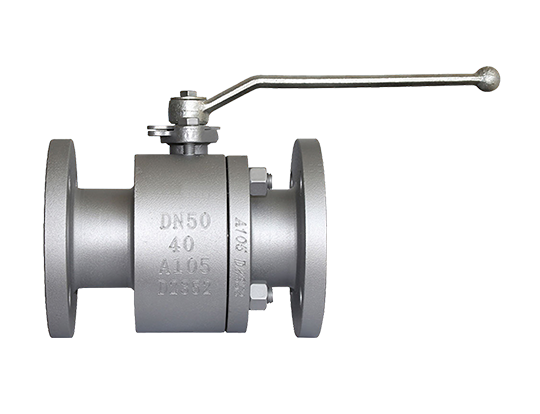

A ball valve is a type of quarter-turn valve that uses a spherical ball with a hole through its center to control the flow of liquids or gases. Known for their durability, tight sealing, and ease of operation, ball valves are widely used in residential plumbing, industrial piping systems, oil and gas pipelines, chemical plants, and water treatment facilities.

What Is a Ball Valve?

A ball valve consists of a ball with a bore (hole) mounted inside the valve body. When the valve handle is turned 90 degrees, the bore aligns with the pipe, allowing fluid to flow through. Turning the handle again rotates the ball, blocking the passage and stopping flow.

The design provides a tight seal, even after long periods of use, and makes ball valves ideal for both on/off and throttling applications.

Key Components

Valve Body: The outer casing that holds all internal parts.

Ball: The main component with a drilled hole, which controls flow.

Seats: Usually made of PTFE or similar material, they seal the ball to prevent leaks.

Stem: Connects the ball to the handle and rotates it.

Handle/Actuator: Allows manual or automated operation.

Types of Ball Valves

1. Two-Way Ball Valve

The most common type, used to start or stop flow in one direction.

2. Three-Way and Four-Way Ball Valves

Used to divert flow between different paths or mix fluids.

3. Full Port (Full Bore) Valve

Offers no restriction; the hole in the ball is the same size as the pipe.

4. Reduced Port (Standard Bore) Valve

Has a smaller hole, creating some restriction but reducing cost.

5. Trunnion Mounted Ball Valve

Designed for high-pressure applications with extra support for the ball.

6. Floating Ball Valve

The ball is held in place by the seats and moves slightly to seal under pressure.

Advantages of Ball Valves

Quick Operation: 90° turn for full open or close.

Leak-Proof Seal: Excellent sealing capabilities, even after repeated use.

Durable: Withstands high pressure, temperature, and corrosive media.

Low Maintenance: Simple design and fewer moving parts.

Versatile: Works in a wide range of applications and fluids.

Common Applications

Water and wastewater systems

Oil and gas pipelines

HVAC systems

Chemical processing

Food and beverage industry

Residential and commercial plumbing

Conclusion

Ball valves are a robust and efficient choice for fluid control in both industrial and domestic settings. Their simple mechanism, reliable sealing, and long service life make them one of the most widely used valve types in modern piping systems. Whether you need fast shut-off or reliable flow control, a ball valve delivers performance you can count on.