Aspects of galvanized steel wire strand

2023-11-16

Galvanized steel wire strand is a type of steel wire product that has been coated with a layer of zinc through the process of galvanization. This coating provides corrosion resistance, making the strand suitable for outdoor and corrosive environments. Galvanized steel wire strands are commonly used in various applications, particularly in the construction industry for overhead power lines, communication cables, and fencing. Here are key features and aspects of galvanized steel wire strand:

1. Material:

- The base material is typically high carbon steel, which provides strength and durability. Galvanized steel wire strands may also be made from low carbon or medium carbon steel depending on the specific requirements.

2. Galvanization Process:

- Galvanization involves coating the steel wire strand with a layer of zinc to protect it from corrosion. This can be achieved through hot-dip galvanization or electroplating. Hot-dip galvanization involves immersing the steel in a bath of molten zinc, while electroplating involves applying a zinc coating through an electrochemical process.

3. Corrosion Resistance:

- The zinc coating on the steel wire strand serves as a protective barrier against corrosion. This makes galvanized strands suitable for outdoor applications where exposure to moisture, weather, and corrosive elements is a concern.

4. Applications:

- Galvanized steel wire strands are widely used in the construction industry for various applications, including the following:

- Guy Wires: Used for supporting structures such as utility poles and communication towers.

- Messenger Wires: Used in overhead power lines and communication cables.

- Stay Wires: Used for supporting structures and preventing swaying or movement.

- Fencing: Used in the construction of fencing for added corrosion resistance.

5. Strength and Durability:

- Galvanized steel wire strands retain the strength characteristics of the underlying steel, making them suitable for applications that require high tensile strength.

6. Flexibility:

- The galvanized steel wire strand remains flexible, allowing for easy handling and installation, particularly in applications like cable or wire rope.

7. Standard Specifications:

- Galvanized steel wire strands are often manufactured to comply with industry standards and specifications, ensuring consistency and quality. Common standards include ASTM A475 and ASTM A363.

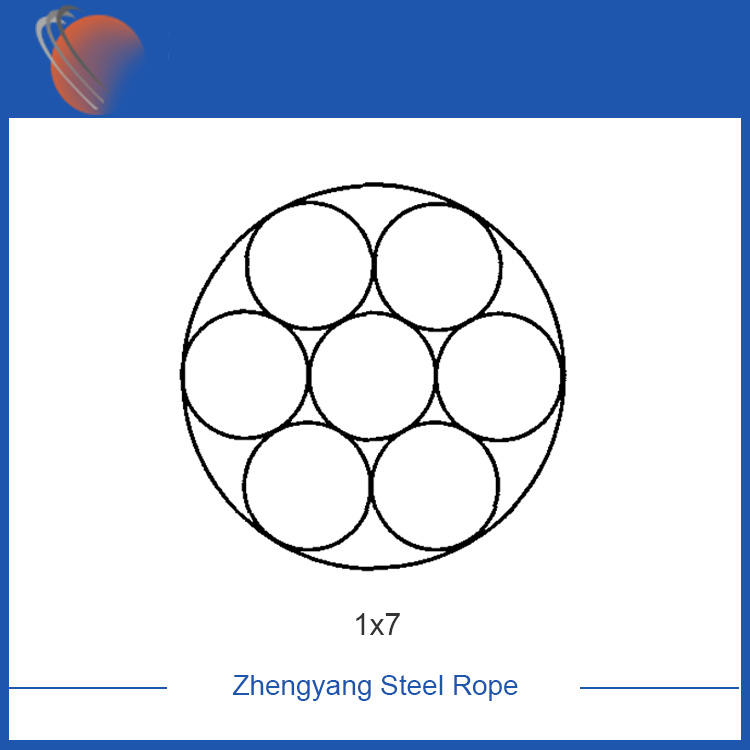

8. Diameter and Construction:

- Galvanized steel wire strands are available in various diameters and constructions, with common constructions including 1x7, 1x19, and 7x7. The choice depends on the specific application and load requirements.

9. Handling and Storage:

- During handling and storage, care should be taken to prevent damage to the galvanized coating. Proper storage practices help maintain the corrosion resistance of the wire strand.

10. Installation Considerations:

- During installation, it's essential to use proper techniques and tools to avoid damaging the galvanized coating. Precautions should be taken to prevent scratches, abrasions, or other forms of mechanical damage.

Galvanized steel wire strands offer a cost-effective solution for applications that require corrosion resistance and high tensile strength. Their versatility makes them a popular choice in the construction of various structures where durability and reliability are paramount.