Applications of Metal Round Dense Connectors Circular

2024-07-25

Metal round dense connectors, specifically circular connectors, are used in various applications requiring reliable and robust electrical connections. These connectors are designed to connect and disconnect electrical circuits quickly and securely while withstanding environmental challenges and mechanical stress. Here’s a comprehensive overview of circular metal round dense connectors, including their features, benefits, applications, and considerations:

Features

1. Design and Construction:

- Shape: Typically circular in design, which allows for symmetrical connections and compact packaging.

- Materials: Made from high-strength metals such as aluminum, stainless steel, or brass, which provide durability and resistance to mechanical stress and environmental conditions.

- Density: Dense connectors feature a high number of contact pins or sockets in a compact arrangement, allowing for multiple connections within a small footprint.

2. Contact Types:

- Pins and Sockets: Utilize metal pins and sockets to establish electrical connections, often gold-plated or nickel-plated to enhance conductivity and resistance to corrosion.

- Insulation: Equipped with insulating materials to prevent short circuits and ensure safe operation.

3. Locking Mechanisms:

- Threaded Couplings: Many circular connectors use threaded couplings or bayonet-style locks to secure the connector and ensure a reliable connection.

- Quick-Release: Some models feature quick-release mechanisms for easy and fast connection or disconnection.

4. Environmental Protection:

- Seals and Gaskets: Incorporate sealing rings or gaskets to protect against dust, moisture, and other environmental factors.

- IP Ratings: Often have high Ingress Protection (IP) ratings to withstand harsh conditions.

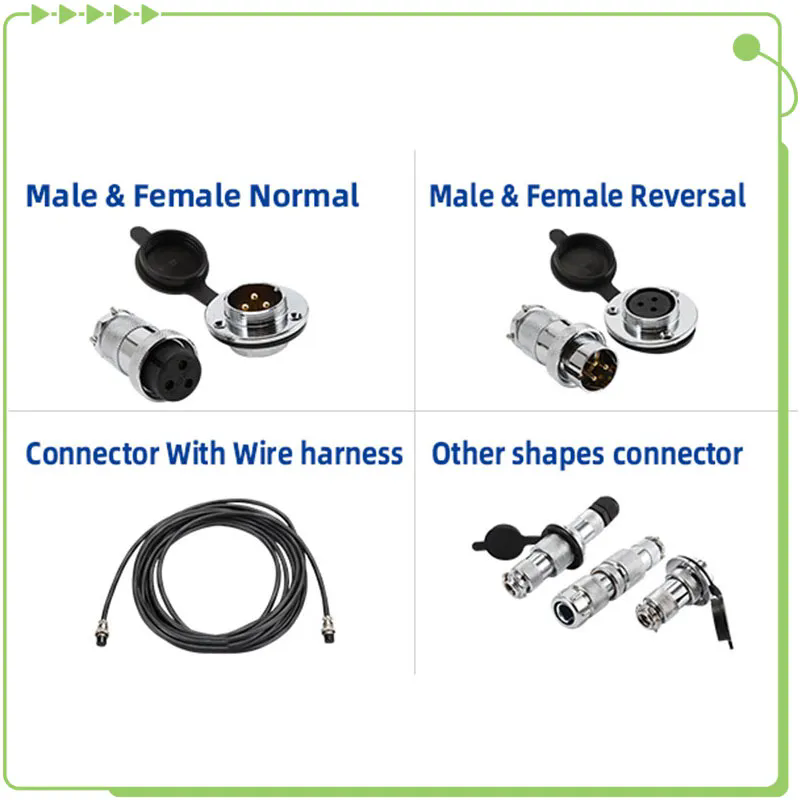

5. Mounting Options:

- Panel Mount: Designed for mounting on panels or enclosures, with various flange and mounting options.

- Cable Mount: Available in versions that allow direct attachment to cables.

Benefits

1. Reliability:

- Durability: Metal construction and dense pin configurations provide robustness and long-lasting performance.

- Secure Connections: Locking mechanisms ensure that connections remain secure and reliable, reducing the risk of accidental disconnection.

2. High-Density Design:

- Compact Size: Dense connectors offer multiple connections in a small form factor, saving space and reducing the number of connectors needed.

- Efficient Wiring: Allows for more efficient and organized wiring in complex systems.

3. Environmental Resistance:

- Protection: Sealed designs protect against environmental factors such as dust, moisture, and extreme temperatures.

- Corrosion Resistance: Metal materials and plating offer resistance to corrosion and wear.

4. Versatility:

- Wide Range of Applications: Suitable for a variety of applications across different industries, including aerospace, military, industrial automation, and telecommunications.

Applications

1. Industrial Automation:

- Control Systems: Used in control panels and machinery to connect sensors, actuators, and other components.

- Robotics: Connects various parts of robotic systems, ensuring reliable communication and power distribution.

2. Aerospace and Defense:

- Avionics: Utilized in aircraft and spacecraft for reliable electrical connections in critical systems.

- Military Equipment: Used in military communication and control systems where reliability and durability are essential.

3. Telecommunications:

- Network Equipment: Connects components in telecommunications equipment, including routers, switches, and base stations.

4. Automotive:

- Vehicle Electronics: Connects various electronic systems within vehicles, including infotainment, navigation, and safety systems.

5. Medical Equipment:

- Diagnostic and Monitoring Devices: Provides reliable connections for medical diagnostic and monitoring equipment.

Considerations

1. Size and Configuration:

- Pin Count: Select a connector with the appropriate number of pins or sockets for your application’s requirements.

- Form Factor: Ensure the size and mounting options match your design and installation constraints.

2. Environmental Requirements:

- Sealing: Choose connectors with appropriate sealing for your environmental conditions, such as dust or waterproof ratings.

- Temperature Range: Ensure the connector can operate within the temperature range required for your application.

3. Electrical Specifications:

- Current and Voltage Ratings: Verify that the connector’s current and voltage ratings are suitable for your application’s power requirements.

- Signal Integrity: For high-frequency or signal-sensitive applications, consider connectors designed to maintain signal integrity.

4. Compatibility:

- Interchangeability: Ensure that the connectors are compatible with other components in your system, including cable and panel mount fittings.

- Standards Compliance: Check if the connectors comply with industry standards and regulations relevant to your application.

Conclusion

Metal round dense circular connectors are essential components for establishing reliable and secure electrical connections in various applications. Their robust construction, high-density design, and environmental protection features make them suitable for demanding and space-constrained environments. Proper selection based on size, environmental conditions, and electrical specifications ensures optimal performance and reliability in your systems.