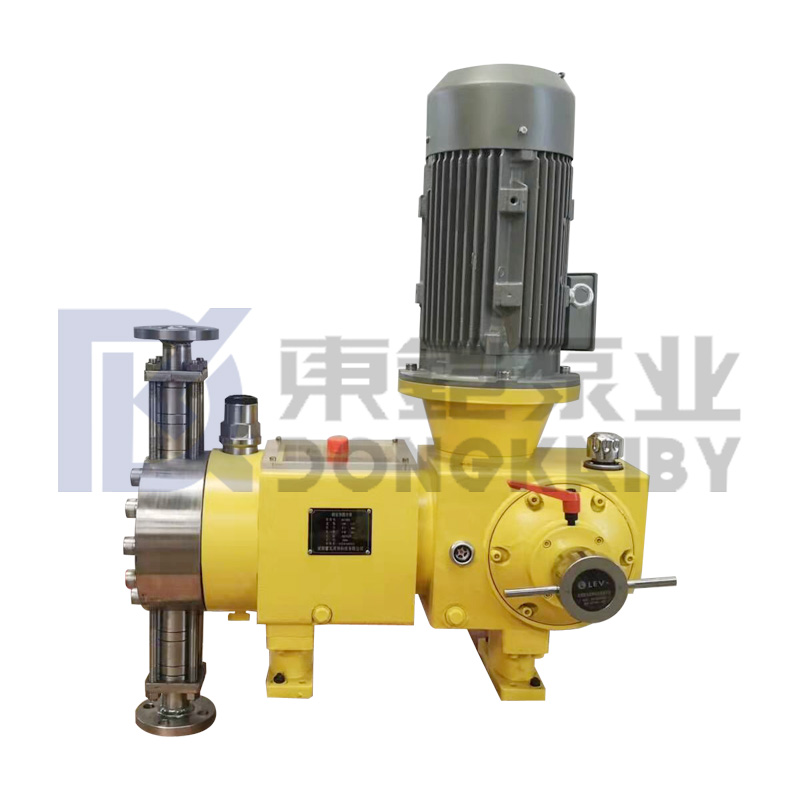

Accurate Hydraulic Diaphragm Metering Pumps

2023-10-18

When accurate hydraulic diaphragm metering pumps run, they require only minimal maintenance. The diaphragms are durable and provide consistently accurate metering. The technology also offers a very high standard of safety; there is a pressure relief valve in the hydraulic end as protection against overload. The multi-layer diaphragms are equipped with a diaphragm rupture warning system as standard. So you can be sure that the feed chemicals will not mix with the hydraulic oil.

It consists of three main devices: (1) the driving device, (2) the adjusting device, and (3) the liquid delivery device. The crankshaft, which reduces motor rotation speed by worm and worm gear, makes the piston reciprocate in the hydraulic oil chamber. This reciprocating movement of the pitston makes the PTFE diaphragm and the liquid, which is isolated by the diaphragm, suck and discharge. Each pump has an internal pressure relief valve to protect it from overpressure conditions.

The flow rate can be adjusted via a unique adjusting mechanism from 0 to 100%. The adjustment can be carried out when the pump is in operation or at a stop. The steady-state accuracy is 1% from 30% to 100% of the maximum output. Automatic operation is achieved by a variable-speed drive.

Dongkai Accurate Hydraulic Diaphragm Pumps are suitable for cross-flow, vaporizing, flammable, explosive, or toxic solutions. It can also transport suspended or moderately viscous liquids. A double diaphragm with a diaphragm rupture detection system is available to prevent accidents caused by the mixture of hydraulic oil and liquid after the diaphragm ruptures.

The industries in which accurate hydraulic technology is used are: Oil/gas production (onshore/offshore) Refineries Chemical / petrochemical industry Pharmaceuticals & cosmetics Food production Packaging industry (bottling pumps)